What are High Tensile Fasteners?

What are high tensile fasteners? They are a specific type of fastener designed to withstand high levels of stress and tension. ‘Tensile strength’ refers to the ability of a material to resist forces without breaking or permanently deforming, and accordingly, high-tensile nuts and bolts represent a particularly strong type of fastener. This doesn’t always mean they’re the best option. Like all situations, the correct solution will depend on the engineering requirements of your project to assess and determine the correct type of fasteners for the job. On this page, we look further into High Tensile options to explore this important type of fasteners. For fasteners on the Sunshine Coast, please contact our team for a quality range of high tensile products in different grades and thread pitches.

How are High Tensile Fasteners Different from other Fasteners?

Generally, fasteners are differentiated by the materials they are made with, the process by which they are made, the fastener dimensions, the measurement system (metric or imperial) and the thread pitch (course or fine). With that in mind, the difference between high tensile fasteners and other types of fasteners include:

Materials:

High tensile fasteners are made from carbon or alloy steel. Other types of fasteners are made from different metals; for example, stainless steel fasteners are made from a variety of stainless steel alloys, and titanium bolts from titanium.

Process:

High tensile fasteners are heat treated to achieve their tensile strength. This process achieves strength by reducing internal stresses in the material, reducing brittleness, hardening and toughening. While other types of fasteners may also be heat treated, it is a mandatory aspect of high tensile bolts with a view to achieving enhanced strength.

Dimensions

Bolts come in a wide range of shapes and sizes. Some of the characteristics which may be seen in high tensile bolts that differentiate them from lower strength bolts include a thicker shank & larger head diameter, although these larger aspects are not necessarily indicative of a high tensile bolt.

Thread Pitch

While high tensile bolts are available in both course and fine thread pitches, fine thread pitche offers greater strength, higher resistance to vibration, better precision, and versatility (a fine thread pitch is more suitable for smaller diameter bolts). Fine thread pitches are commonly used in automotive bolts for these reasons.

System

Bolts are available in metric and imperial systems, and high tensile fasteners are no exception. The system is important because when matching a bolt, the system must also be matched to ensure an accurate fit. Bolt-In Co stocks high tensile bolts in both metric and imperial systems, in course & fine thread pitches (metric) and UNF / UNC threads (imperial).

When to Use High Tensile Fasteners

High tensile fasteners are used when superior strength and durability are necessary. Examples of high tensile fastener applications include:

Structural Applications

Infrastructure construction projects like bridges & buildings may utilise high tensile fasteners.

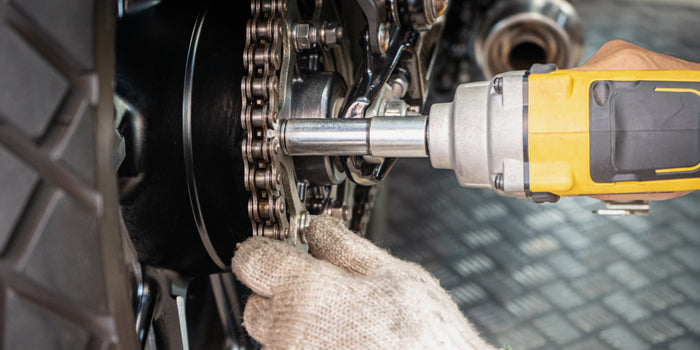

Automotive & Aerospace

With high levels of stress and vibration, automotive and aeronautical engineering relies on high tensile fasteners. As mentioned above, a higher thread pitch is often utilised for a stronger result.

Heavy Machinery & Equipment

The machinery and equipment utilised in industries such as mining, agriculture and construction utilise high tensile bolts, where high levels of stress and vibration are also a factor.

Marine Applications

High Tensile fasteners may also be used in offshore and marine applications where high levels of stress, tension and vibration require a stronger fastener.

When not to Use High Tensile Fasteners

Using high tensile fasteners should only be done when necessary - otherwise, they may be a more expensive solution for a project that doesn’t require them. Examples of when high tensile may not be the best solution include:

Low-Stress Applications

There are many less expensive fasteners which are suitable for low-stress applications.

Corrosive Environments

Balancing the need for strength and corrosion resistance will depend on the specific application. Stainless steel fasteners offer a higher level of corrosion resistance than high tensile fasteners.

High Temperature Environments

High tensile fasteners may lose their strength and durability at high temperatures. In these cases, titanium or nickel alloys may be more appropriate solutions.

Grading the Strength of High Tensile Bolts

The SAE (Society of Automotive Engineers) grading system is a common system use to grade high tensile bolts. This system uses a numeric grade to indicate the tensile strength. The higher the grade, the stronger the fastener. It’s not the only system used. Other systems, such as ASTM (American Society for Testing and Materials) is another example.

High Tensile Fasteners at Bolt-In Co

Enquire with Bolt-In Co Sunshine Coast for the fasteners for your project. We have a wide range of high tensile in stock, and can easily order products in if we don’t stock them (depending on quantity).